Vibration monitoring with sensors notifies teams of abnormalities in order to determine when maintenance is needed with color-coded severity alarms and trending data. Further analyzation with handheld vibration testers such as the 805 FC following an alarm can help your team identify the fault of abnormalities. This enables your team to perform the right corrective action at the right time. Spend less time taking manual readings during routes and more time addressing problems with Fluke 3561 FC Vibration Sensors.

In pumps, motors and most other rotating equipment, the four most common faults are misalignment, looseness, imbalance, and bearing wear. All these can cause increased power consumption, vibration, and stress on shafts.

Imbalance can cause a number of issues including:

If the baseplate or foundation is uneven or if one of the motor's feet is uneven, soft foot can occur, causing excess vibration.

Misalignment can cause:

A misaligned shaft will transmit damaging cyclical forces along the shaft and into the motor, leading to excess wear on the motor and increasing the mechanical load.

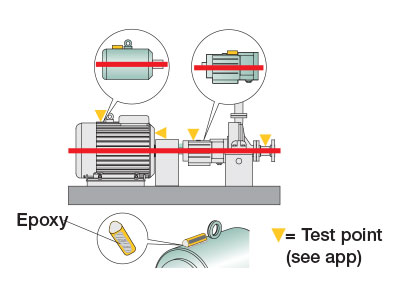

This diagram shows the proper placement and test point for motor vibration sensors

The shaft, foundation, or a component may become loose. This causes forces that lead to excessive vibration and increases the wear in the bearings and seals. It may also cause baseplate problems, including soft foot; loose bolts; cracks in a frame; or improper fit between components, including impeller clearances. If not identified and corrected, looseness will shorten the asset's and other components' lives, ultimately causing failure.

Bearing wear is usually caused by other factors acting on the bearings. If the bearings are failing prematurely, the other low-level faults (imbalance, misalignment, or looseness) may be the cause. For example, moderate misalignment may or may not increase in severity over time, but the effects of this misalignment will add to the stress on bearings and seals. Vibration sensors display all the faults found in a machine so that potential candidates for root cause failure may be identified before bearing wear occurs. Even if misalignment is not extreme, it should still be diagnosed and corrected as soon as possible to avoid collateral damage to the asset's bearings and seals.

The Fluke 3561 FC Vibration Sensor sets up quickly and provides insights remotely. Install it in under an hour and let the Fluke Connect™ system grade asset health.

Increase uptime by viewing trends and receiving alarms on your smart device or computer within seconds of an abnormality.

Request a virtual demo